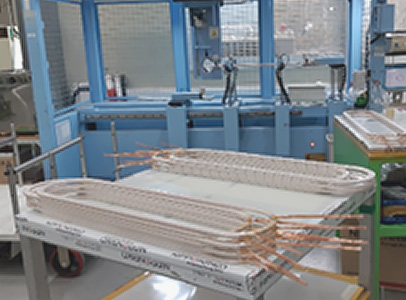

OVERHAUL & REPAIR

SN systematically establishes maintenance plans according to customer requests such as power generation plants, steel plants, cement/paper plants, oil refining/chemical plants, and pump stations, and supports periodic inspection of the condition of motors/generators and stable operation of facilities.

In addition, SN responds to emergency requests from customers with a 24-hour response system at all times, and eliminates problems that may occur in the future by accurately identifying and analyzing the cause when repair work is in progress. Also, since reverse engineering is possible by the design team, it is supported for improved facility operation.

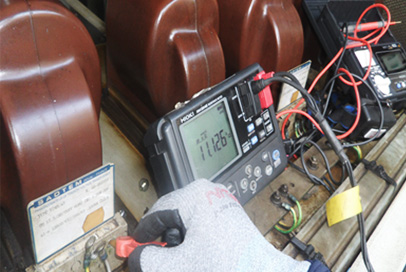

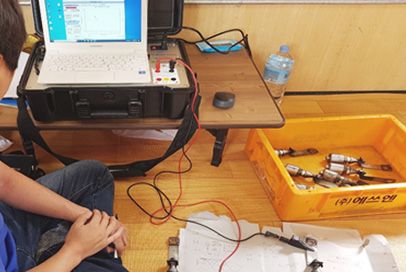

We realize customer satisfaction through the best technology and diagnostic and testing equipment that can evaluate the soundness of rotating equipment through insulation diagnosis and characteristic testing of electric motors/generators.

Planned Preventive Maintenance - Electric motor/Generator OVERHAUL

Induction Motor

| Capacity | 0.4KW to 30MW |

|---|---|

| Voltage | Up to 13.2 kV |

| Pole | 2 ~ 36P |

Direct Current Motor

| Capacity | 0.75KW to 5000KW |

|---|---|

| Voltage | Up to 2.0 kV |

| Pole | 2 ~ 36P |

Electric motor for Vehicle

| Capacity | 30KW to 2MW |

|---|---|

| Voltage | Up to 3.0 kV |

| Pole | 2 ~ 8P |

Synchronous Generator & Motor

| Capacity | 5.5KW to 50MW |

|---|---|

| Voltage | Up to 2.2 kV |

| Pole | 2 ~ 36P |

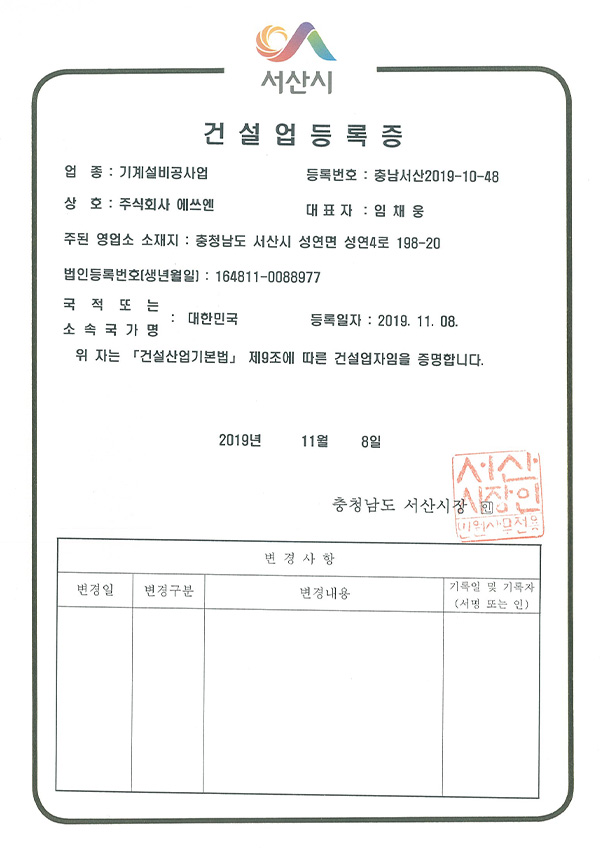

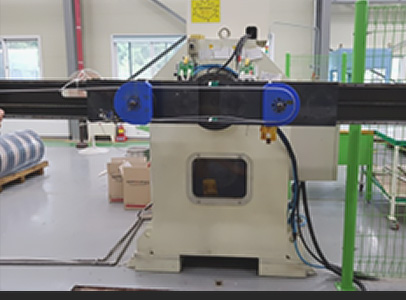

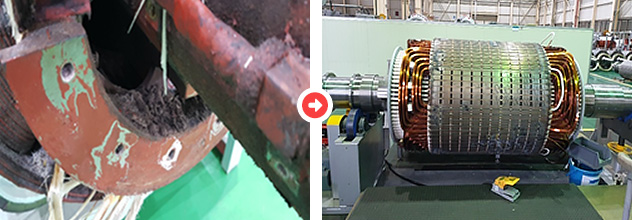

Repair - Rewinding

Induction motor rewinding

Coil Loop Winding

Coil Winding

Coil Taping

Forming

Surge Test

CORE 청소

Coil Incerting

Vacuum impregnation(VPI)

Drying

Impregnation, Drying completed

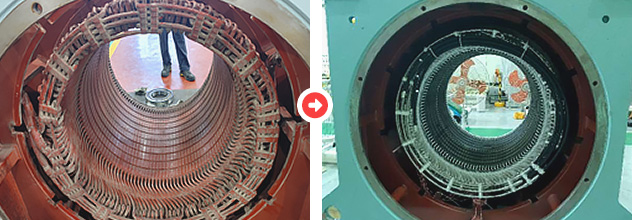

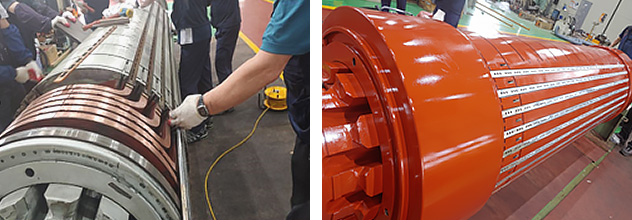

Generator rotor rewinding

Generator stator rewinding

Generator excitation repair

Generator rotor repair

Tests and diagnostics for Properties

Performance test

- Full load characteristics(Efficiency, Power factor)

- Torque Properties(Starting torque, Pull-up torque, Maximum torque)

- Temperature rise test

- Withstand voltage

- Measurement of noise/vibration

Inspection of stator electrical properties

- Insulation resistance test

- Polarization Index (PI) Test

- AC current Test

- Dielectric loss tangent test

- Partial Discharge (PD) Test

- Winding resistance

- Tan-Delta

- EL-CID

Inspection of stator mechanical properties

- The robustness of the slots wedge

- Air gaps

- Winding End Impact Test

Inspection of rotor electrical properties

- PI Test

- Voltage Drop Test

- Partial Discharge Test

- RSO

- Insulation Resistance

- Winding resistance, etc.

Inspection of rotor mechanical properties

- Bearing & Retaining Ring

- The robustness of the slots wedge

- Shop Balancing (~15 tons)